Fasteners

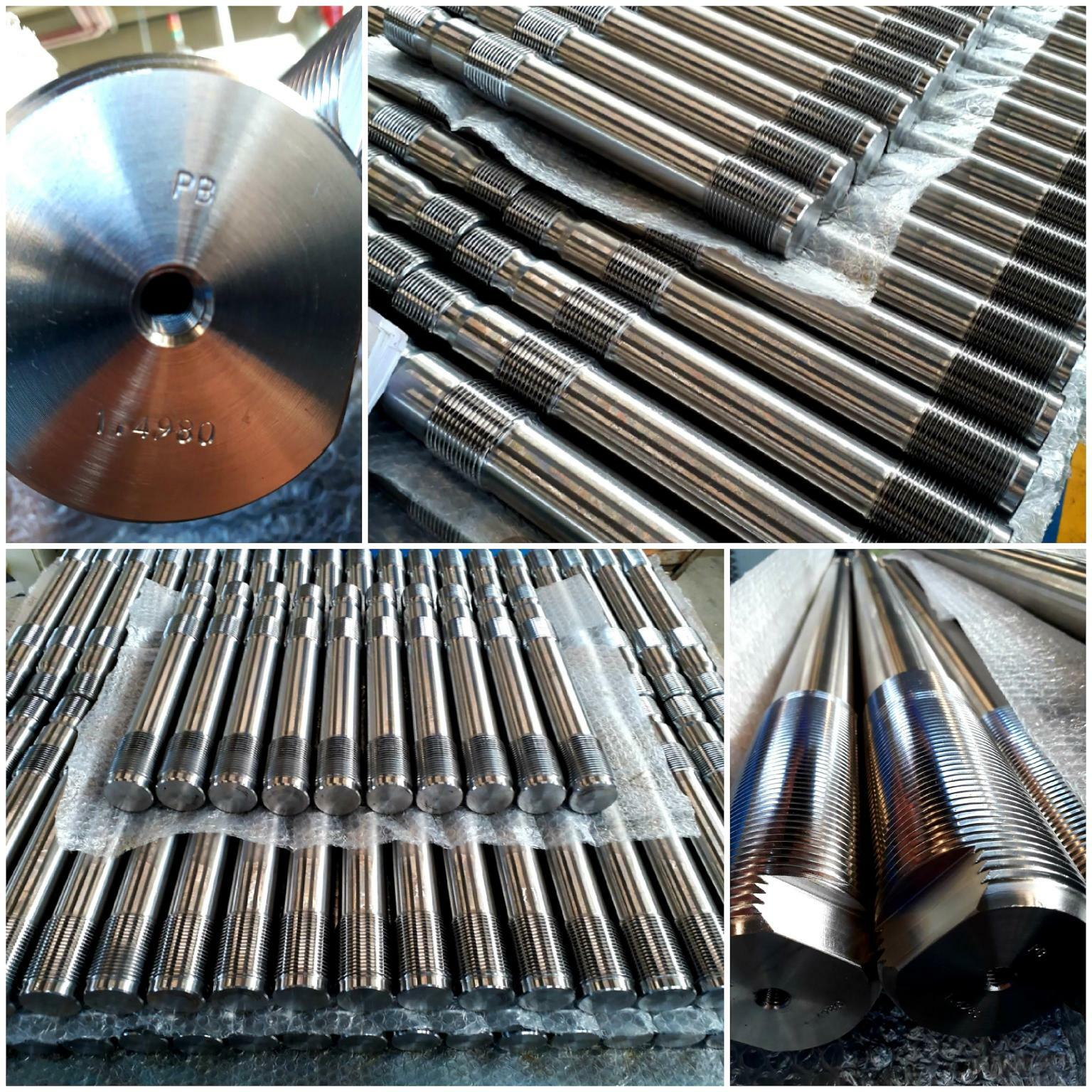

Studbolts

Studbolts

We offer broad variety of easily accessible materials with short lead times. Our extensive stock of fully certified materials empowers us to rapidly respond to market needs by manufacturing high quality products from ¼” to 7” (Imperial) and M6 to M140 (Metric).

Hex Bolts

Hex Bolts

STOCK - EACH FASTENER IS DISTINTIVELY CREATED

Hex bolts feature a hexagonal head and are offered in both partially and fully threaded versions, available in heavy and standard patterns. They are commonly employed in machinery and construction settings, particularly in projects like bridges, highway structures, and buildings. Our manufacturing capabilities encompass a broad spectrum to cater to customer specifications, including a variety of coatings (such as ZINC, HDG, PTFE, and others) in both Inch and Metric sizes, all accompanied by full certification.

Engineering Stud

Engineering Stud

Engineering Studs also referred to as double ended studs, feature threading at both ends with a smooth and unthreaded section in the middle. These specialized bolts are primary designed for use in high pressure valves, blowout preventers (BOPs), and similar equipment.

ASTM A193 B7, B7M, B16, B8, B8M, A320 L7, L7M, etc.

Size ranges:

M6 to M100 (Metric coarse thread)

¼” UNC to 1” UNC

1-1/8” UN8 to 4” UN8

Collar Bolts

Collar Bolts

Collar Bolts are usually custom designed to align with their intended application. Their main feature is having a square or hexagonal extension beyond the threaded portion, designed for wrench use to prevent the bolt from turning while tightening or removing the nuts.

Collar Bolts have several uses, including but not limited to alignment and spacing, providing a locking feature, ensuring even load distribution, and preventing rotation.

Size ranges:

M6 to M100 (Metric coarse thread)

¼” UNC to 1” UNC

1-1/8” UN8 to 4” UN8

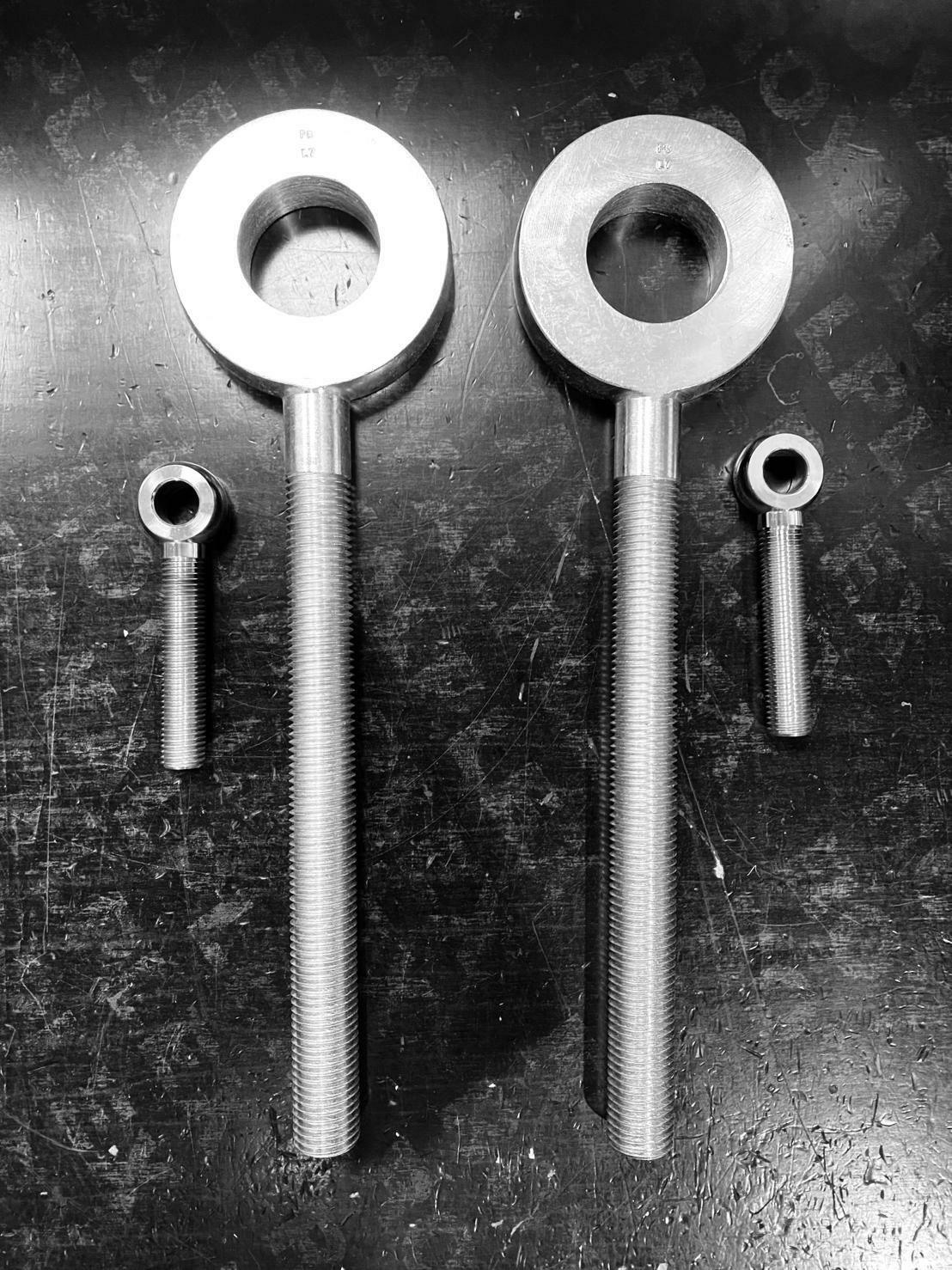

Eye Bolts

Eye Bolts

Eye bolts serve a crucial role in lifting and rigging equipment, available in a range of materials like steel, stainless steel, and brass. They come in various sizes and thread types to suit diverse project needs. Eye bolts are categorized into regular, shoulder, and swivel types. Our commitment to providing convenient access to a diverse selection of materials with quick turnaround times enables us to promptly meet customer demands and produce a wide array of certified, top-notch products ranging from M6 extending up to M36, in accordance with our clients’ specifications.

Socket Cap Screw

Socket Cap Screw

Socket Cap Screw also recognized as an Allen screw or Allen bolt is characterized by having a cylindrical head and a hexagonal socket (compatible with an Allen or hex key) and is utilized for tightening and loosening. These Screws are offered in an extensive range of sizes, available in both pre-made and raw material forms. The size options encompass M6 to M100 (Metric coarse thread), ¼” UNC to 1” UNC, and 1-1/8” UN8 to 4” UN8. We tailor the product to meet the unique specifications of our clients.

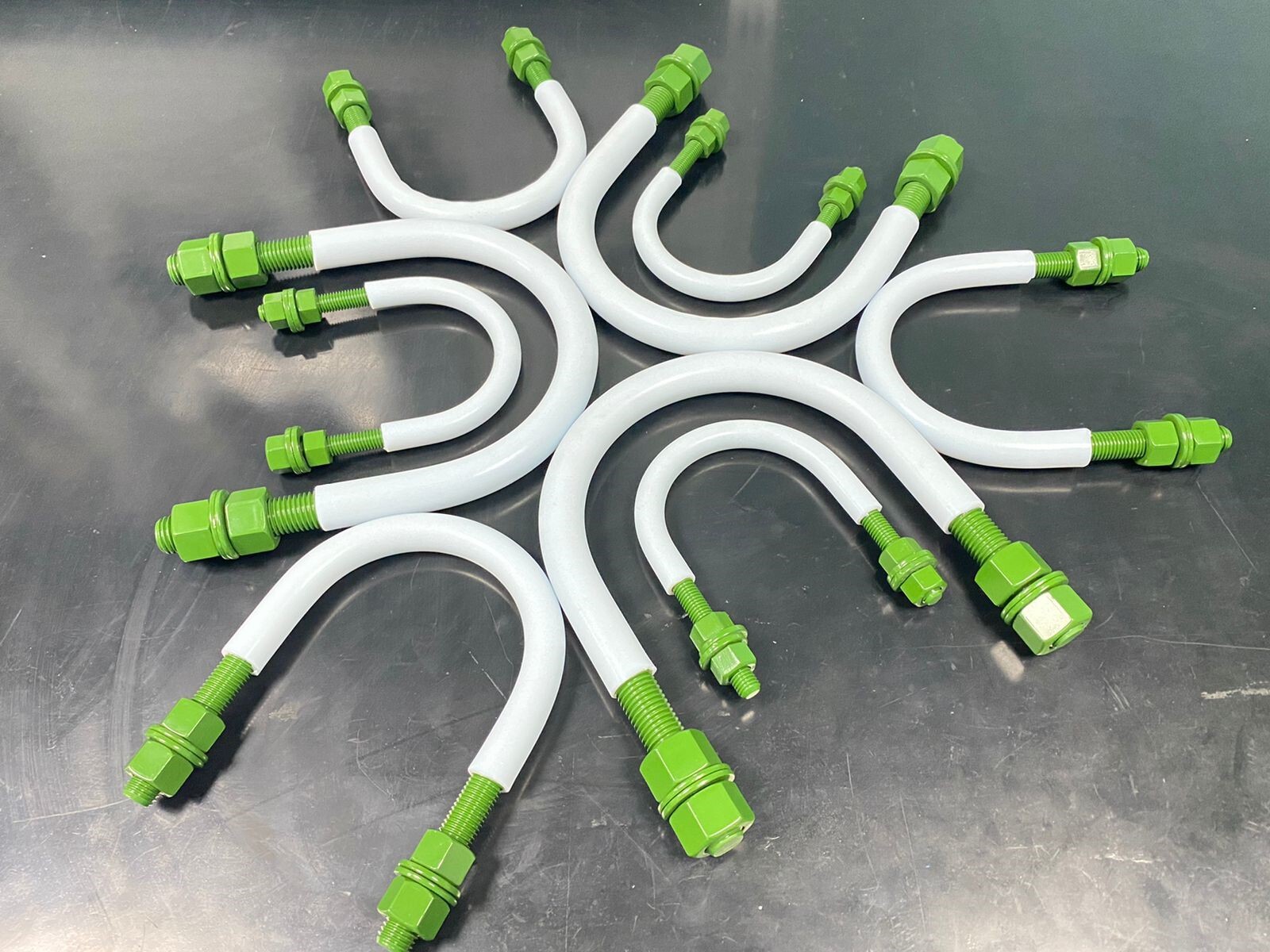

U Bolts / U Clamps

U Bolts / U Clamps

U Bolts / U Clamps are commonly employed for the secure fastening of pipes, rods, and other cylindrical objects. To secure the object firmly in place, the U-bolt encircles it and is then tightened using nuts positioned at each end of bolt.

U-bolts are fabricated from a variety of materials, such as stell and stainless steel, and they are available in various sizes and thread types tailored to suit the needs of diverse projects. We maintain an extensive inventory of sizes in both pre-made and raw material forms, encompassing: Metric coarse thread: M4 (1/8”) to M36 (1.1/2”) with pipe size of ¼” to 36”. Additionally, we offer customization options to meet specific requirements.

We stock a wide range of sizes in both ready-made and raw materials, including:

Metric coarse thread: M6 to M100

UNC: ¼” to 1”

UN8: 1-1/8” to 4”

We customize the product according to specific requirements.

Anchor / J / L Bolts

Anchor / J / L Bolts

Anchor bolts, recognized as J-bolts, represent a category of fasteners employed for the secure attachment of objects to concrete foundations. They are available in a variety of sizes and configurations to suit diverse applications and are typically utilized in construction tasks like anchoring walls, columns, and equipment. The proper installation of these bolts is essential for ensuring the structural integrity of the building.

Our specialized in-house equipment enables us to craft fully customized products within a short timeframe. We maintain a comprehensive inventory of raw materials in various sizes, ranging from M6 to M100 (Metric coarse thread). The materials we offer include Carbon Steel, Mild Steel, and Stainless Steel, with different grades available such as A36, 8.8, B7, S275JR, 316, and 304.

Materials:

Carbon Steel, Mild Steel

Grades:

A36, 8.8, B7, S275JR

We customized the product as per requirement

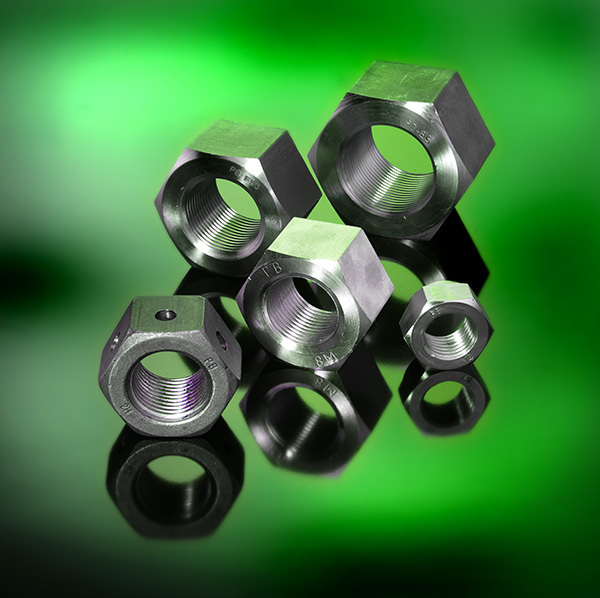

Hex Nuts

Hex Nuts

We maintain a diverse inventory of Hex Nuts, which are nut varieties with a hexagonal shape. These nuts are compatible with various machine-threaded fasteners, including anchors, bolts, screws, studs, and threaded rods. Hex nuts are commonly employed in conjunction with other fasteners, typically bolts, to securely fasten and complete various connections. Additionally, our selection includes other hex nut variations like Anco Lock Nuts, Tommy Hole Nuts, and customized nut solutions to cater to specific needs.

Hex Plugs

Hex Plugs

High-pressure hex plugs represent a specific threaded fitting employed across diverse industrial settings, especially in scenarios necessitating the containment or regulation of fluids or gases under elevated pressures. These hex plugs are engineered to thread securely into openings, effectively sealing them to prevent any potential leaks.

Here are several typical uses and applications of high-pressure hex plugs:

- Hydraulic and Pneumatic Systems

- Oil and Gas Industry

- Chemical Processing

- Heat Exchangers

- High-Pressure Testing and Instrumentation

- Pressure Valves

We offer hex plugs in sizes that adhere to standard pressure ratings as well as in accordance with clients' specific drawings and requirements.

CNC Machined Bolts

CNC Machined Bolts

These bolts are meticulously crafted to fulfil precise specifications and provide benefits such as exceptional precision, stringent tolerances, and intricate designs.

They find application in various sectors, including but not limited to:

- High-Performance Machinery

- Oil and Gas Industry

- Tailored Fixtures and Tooling

- Customized Fastening Solutions

The dimensions and specifications of these machined bolts are custom-tailored to match the client's drawings and requirements.

Stock Material

Stock Material

ASTM A193 : B5, B6, B7, B7M, B16,

CLASS 1: B8, B8C, B8M, B8P, B8T, B8LN, B8MLN

CLASS 1A: B8A, B8CA, B8MA, B8PA, B8TA, B8LNA, B8MLNA, B8NA, B8MNA, B8MLCuNA

CLASS 1B: B8N, B8MN, B8MLCuN

CLASS 1C: B8R, B8RA, B8S, B8SA

CLASS 1D: B8, B8M, B8P, B8LN ,B8MLN ,B8N, B8MN ,B8R ,B8S

CLASS 2 : B8 ,B8C, B8P, B8T, B8N, B8M, B8MN, B8MLCuN

CLASS 2B: B8M2, B8

CLASS 2C: B8M3

ASTM A320 : L7, L7M,L43,L1

CLASS 1: B8, B8C, B8M, B8P,B8F, B8T, B8LN, B8MLN,

CLASS 1A: B8A, B8CA, B8MA, B8PA,B8FA, B8TA, B8LNA,B8MLNA

CLASS 2: B8,B8M, B8C, B8P, B8F, B8T:

ASTM A194

2H, 2HM, 7M , 3, 4, 7, 16, 6, 6F, 8, 8C, 8M, 8T, 8F, 8P, 8N, 8MN, 8LN, 8MLN, 8MLCuN,9C, 8A, 8CA, 8MA, 8TA, 8FA, 8PA, 8NA, 8MNA, 8LNA, 8MLNA, 8MLCuNA, 8R, 8RA, 8S, 8SA.

ASTM A105

ASTM A307 B

ASTM A350 LF2

ASTM A437 B4B (UNS S42200)

ASTM A453 660 A-B-C-D (UNS S66286/W.Nr.1.4980)

ASTM A182 F51 (UNS S31803/W.Nr.1.4462)

ASTM A182 F53 (UNS S32750/W.Nr.1.4468)

ASTM A182 F55 (UNS S32760/W.Nr.1.4496)

ASTM A182 F60 (UNS S32205/W.Nr.1.4462)

ASTM A182 F44 (UNS S31254/W.Nr.1.4547)

ASTM A182 F310 (UNS S31000/W.Nr.1.4805)

ASTM A182 F904L (UNX n08904/W.Nr.1.4539)

ASTM A540 B21,B22,B23,B24.

ASTM A564 630 (UNS S17400)

ASTM F467 Titanium Gr.2,5.

Hastelloy® ALLOY C-276 (UNS N10276/W.Nr.2.4819)

INCONEL® ALLOY 625 (ASTM B446/ ASTM F467/F468 UNS N06625/W.Nr.2.4856)

INCONEL® ALLOY 718 (ASTM B637/UNS N07718/W.Nr.2.4668)

INCONEL® ALLOY 600 (ASTM B166/UNS N06600/W.Nr.2.4816)

INCONEL® ALLOY 601 (ASTM B166/UNS N06601/W.Nr.2.4851)

INCONEL® ALLOY 925 (ASTM B805/UNS N09925)

INCOLOY® ALLOY 20 (ASTM B473/UNS N08020)

INCOLOY® ALLOY 800H (ASTM B408/UNS N08800)

INCOLOY® ALLOY 825 (ASTM B425UNS N08825/W.Nr.2.4858)

MONEL® ALLOY 400 (ASTM F467/F468/UNS N04400/W.Nr.2.4360)

MONEL® ALLOY K-500 (ASTM F467 /F468/UNS N05500/W.Nr.2.4375)

NIMONIC®80A (ASTM B637/UNS N07080/W2.4952)

NITRONIC® 50 XM-19 (UNS S20910/W.Nr.1.3964)

NITRONIC®60 (UNS S21800)

WASPALOY® (AMS 5708/UNS N07001/W.Nr.2.4654)

EN 10269

C35E (W.Nr.1.1181)

C45E (W.Nr.1.1191)

25CrMo4 (W.Nr.1.7218)

42CrMo4 (W.Nr.1.7725)

40CrMoV4-6 (W.Nr.17711)

41NiCrMo7-3-2 (W.Nr.1.6563)

20CrMoVTiB4-10 (W.Nr.1.7729)

34CrNiMo6 (W.Nr.1.6582)

30CrNiMo8 (W.Nr.1.6580)

X22CrMoV12-1 (W.Nr.1.4923)

X19CrMoNbVN11-1 (W.Nr.1.4913)

X5CrNi18-10 (W.Nr.1.4301)

X2CrNiMo17-12-2 (W.Nr.1.4404)

X5CrNiMo17-12-2 (W.Nr.1.4401) X6NiCrTiMoVB25-15-2 (W.Nr.1.4980)

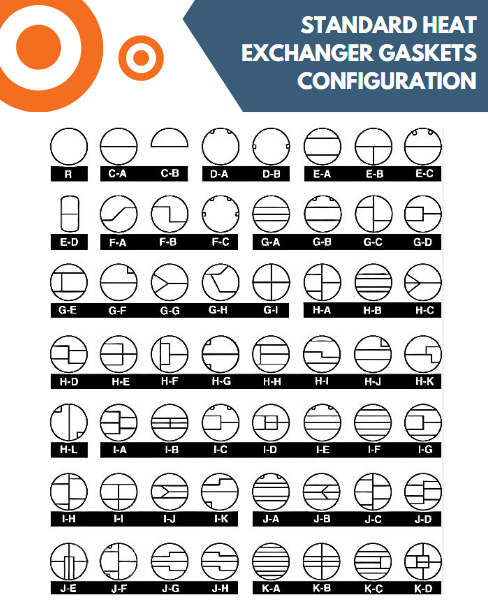

Sealing Gaskets

Sealing Gaskets

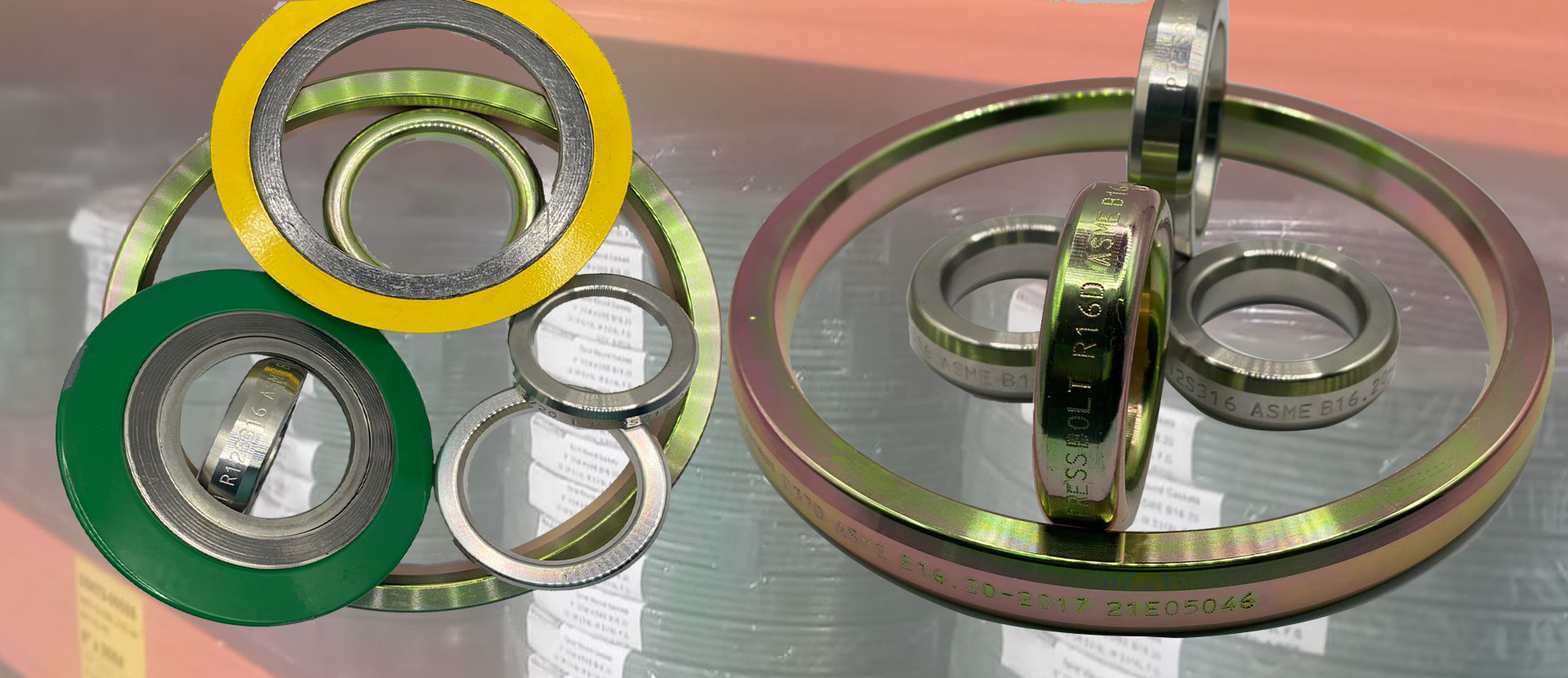

Spiral Wound Gasket

Spiral Wound Gasket

Spiral wound gaskets have the ability to recover under the action of fluctuating loads caused by process fluid pressure and temperature changes, flange face temperature variations, flange rotation, bolt stress relaxation, and creep. The gasket sealing element consists of a pre-formed metallic winding strip with layers of a softer, more compressible sealing material which, during compression, is densified and flows to fill imperfections in the flange surfaces. The metal strip holds the filler, giving the gasket mechanical resistance and resilience. The dimensional requirements of spiral wound gaskets are provided in ASME B16.20. These gaskets are widely used in piping and pressure vessel flange connections, in medium to high pressure and temperature duties.

TYPES OF SPIRAL WOUND GASKETS

Type R have wide range of materials for filler and metallic strip. They are standalone sealing element where the ID is reinforced with several layers of metal winding, filler material is the introduced to offer greater sealing ability. Widely used in tongue to groove, male to female and flat face to recess in vessels, valves and pumps.

Type CR have a solid metal outer ring used as a centring device and compression stop. They are mainly used on raised face and flat face flanges.

The centring ring is designed to guide the gasket on a bolted flange and provide radial strength.

Type RIR are same as type R except that solid inner ring is used to prevent over compression. They have high pressure and high temperature capability and used in male to female flanges in vessels, valves and pumps. The design is also helpful in turbulent applications.

Type CRIR have solid metal inner and outer rings and are best suited for high pressure and high temperature applications. These gaskets prevents turbulence and erosion damage to flanges and prevent damage to the gasket bore and inner windings. The inner ring act as a heat shield and corrosion barrier and eliminate the inward buckling of the sealing element.

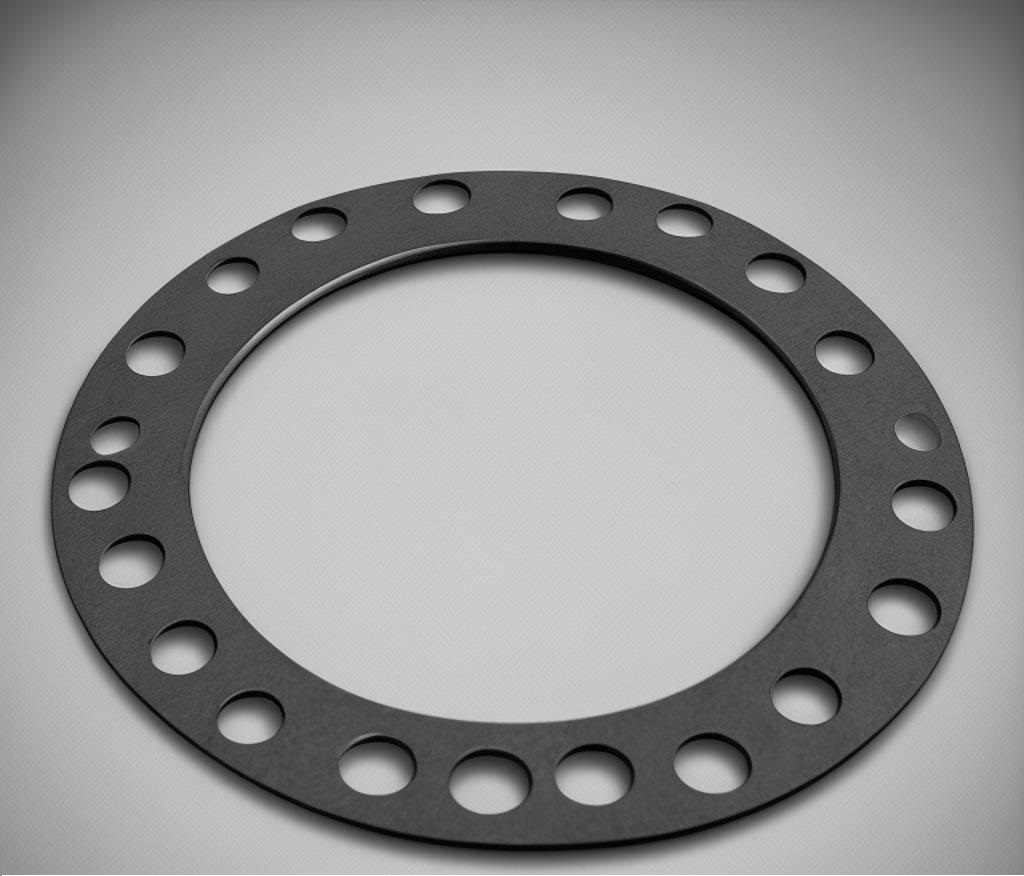

Ring Joint Gasket

Ring Joint Gasket

Ring Joint Gaskets are precision-machined metallic sealing rings with dimensions in accordance with ASTM B16.20, API 6A, and ASME B16.5/16.20.

Ring Joint Gaskets are suitable for high-temperature and high-pressure applications. They are available in several common profiles to suit a variety of industry-standard flanges.

TYPES OF RTJ GASKETS:

Type R Series: R series ring type joint gaskets are available in oval and octagonal shapes. Both types are interchangeable on modern octagonal type grooved flanges. R series gaskets are available up to 5,000 psi.

Type RX Series: RX series ring type joint gaskets are interchangeable with R series in situations that have high pressure with more intense vibrations.

Type BX Series: BX Series ring type joint gaskets are pressure gaskets manufactured and designed for use up to 20,000 psi.

Double Jacketed Gasket

Double Jacketed Gasket

Double Jacketed Gasket Available Materials for Outer Shell: Stainless Steel 304, 316L, 321, 347, 410, Inconel, duplex, Soft Iron, Carbon Steel, PTFE, 4-6 Chrome 1/2 Mo

Filler Material: Nickel, Aluminium, Brass, Copper, Ceramic, Expanded Graphite, Non-Asbestos

Double Jacketed gaskets consist of a metallic outer shell with either a metallic compressed filler or a non-metallic compressed filler material. The filler material gives the gasket resilience, while the metal shell jacket protects the filler and resists pressure, temperature, and corrosion. These gaskets are suitable for use in Boilers, Heat Exchangers, Apparatus Construction, Pumps, and valves, narrow surface sealing, and applications where high-temperature gas is the fluid. These gaskets increase the stability of the joint and reduce its strength and offer high chemical resistance at a wide range of fluids.

Features:

- Available in diameters over 60”

- Can be used for temperatures above 1000F

- Different construction types offered to maximize resiliency

- Standard thickness and pass bar designs are available

- Flexible design allows for pass partitions in heat exchangers

- Relatively quick turnaround even for the most customized gaskets

Other Types of available Jacketed gaskets:

Single Jacketed Gaskets: The filler material is enclosed in a metal jacket, which covers the inside and outside diameter of the gasket.

French-Type Jacketed Gaskets: The filler material is enclosed in a metal jacket, which covers the diameter of the gasket and completely covers the sealing faces on both sides.

Solid Corrugated Metal Gaskets: This is comprised solely of metal and does not contain any non-metallic fillers in its construction

Typical applications

> Heat exchangers

> Gas mains

> Boiler and fues

> Pumps.

> Valve bonnets

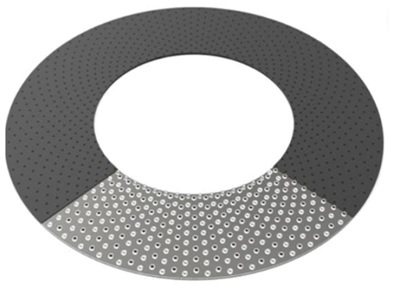

Insulation Kit

Insulation Kit

Available Materials Gasket:

Nitrile-Face, G3, G7, G10, Phenolic, Teflon, Neoprene, Durlon

Sleeve: Phenoloc, Mylar, Polyethylene, Minlon, Nomex

Washer: G3, G7, G10 Steel, Phenoloc

Insulation kit gaskets are manufactured from materials with high compressive strength and stability, which helps prevent stray currents that cause corrosion. These gaskets are made from materials with high dielectric strength, low water absorption, and chemical stability.

Insulation kits are used to seal pipelines and guarantee the safe flow of fluids through pipeline systems. They offer a quicker and cheaper alternative to isolation joints and require little maintenance. The kits are manufactured in accordance with ANSI B16.5 specifications for sizes up to 24”.

Types Of Insulation Kit Gaskets:

Type E Gasket – These gaskets are full-faced and extend to the outside diameter of the flange. They have holes that automatically center them during installation and offer good protection against foreign objects shorting out the flange.

Type F Gasket – These gaskets are raised-faced and extend to the inside diameter of the bolt circle. As they sit just inside the bolt circle, they will automatically center themselves during installation.

Type D Gasket – These gaskets are designed to fit the ring groove of an RTJ flange.

Sleeves: The length of the sleeve must take into account the thickness of the gasket and must not be too short or too long. If it is too short, it fails to protect the bolts, and if it's too long, it could cause problems or break during tension. Sleeves are the best solution for reliability, resistance to aging, and insulating capacity.

Washers: The insulating washers are used to electrically isolate the bolts from other metal parts of the system. The insulating washer material should have a higher resistance to compression, which has an important impact on the performance of the insulating kit.

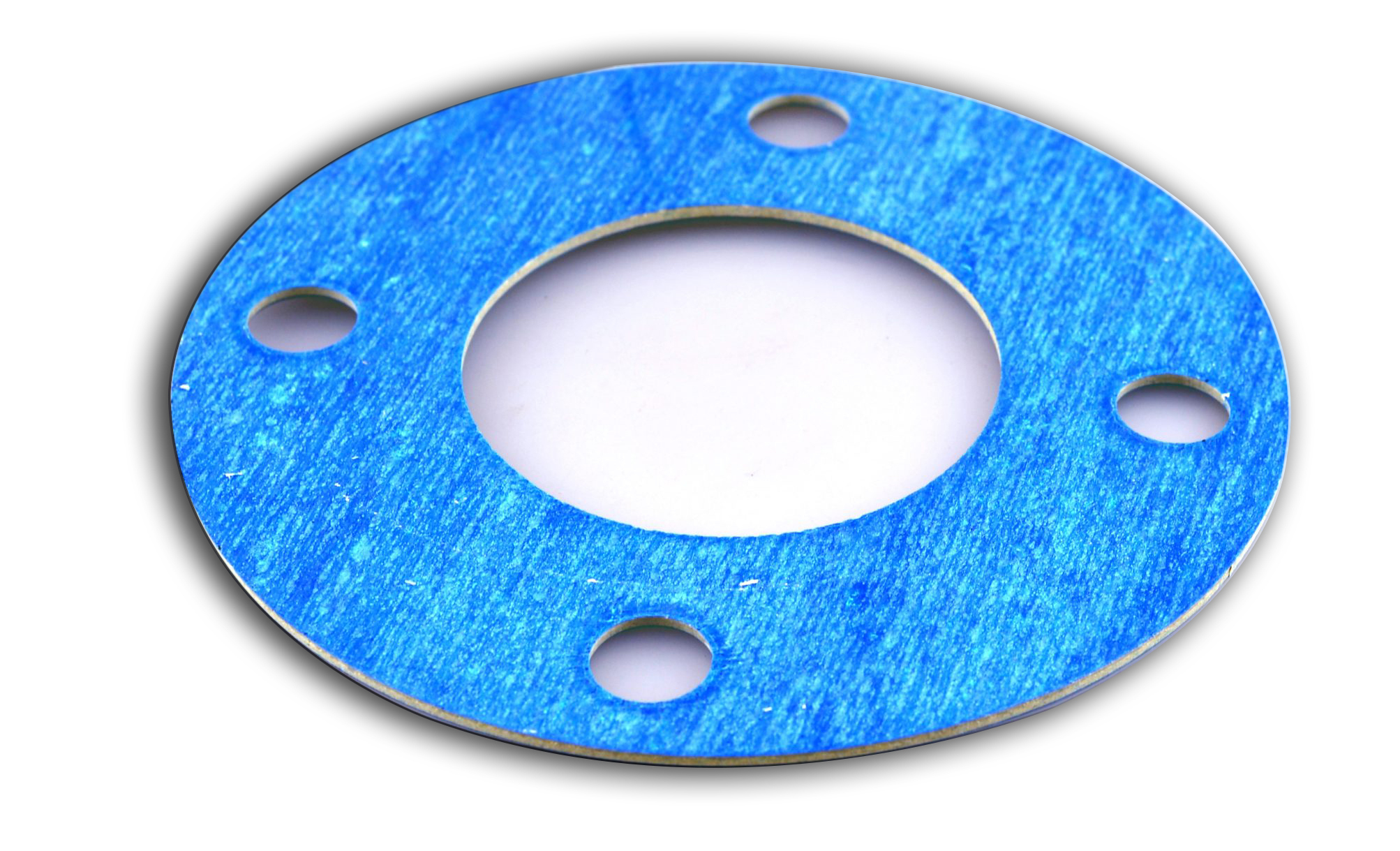

Compressed Non-Asbestos Gaskets

Soft Iron Gasket

Compressed Non-Asbestos Gaskets

- Nitrile bound non-asbestos material with good torque retention and excellent creep resistance.

- These gaskets provides good resistance to oil, solvents and many other media and have good anti-stick properties.

- Typical Tensile strength is above 1500 PSI

TEMPERATURE LIMIT

Maximum – 7500F

Continuous Maximum – 4600F PRESSURE LIMIT

Maximum – 1595 PSI

Continuous Maximum – 725 PSI

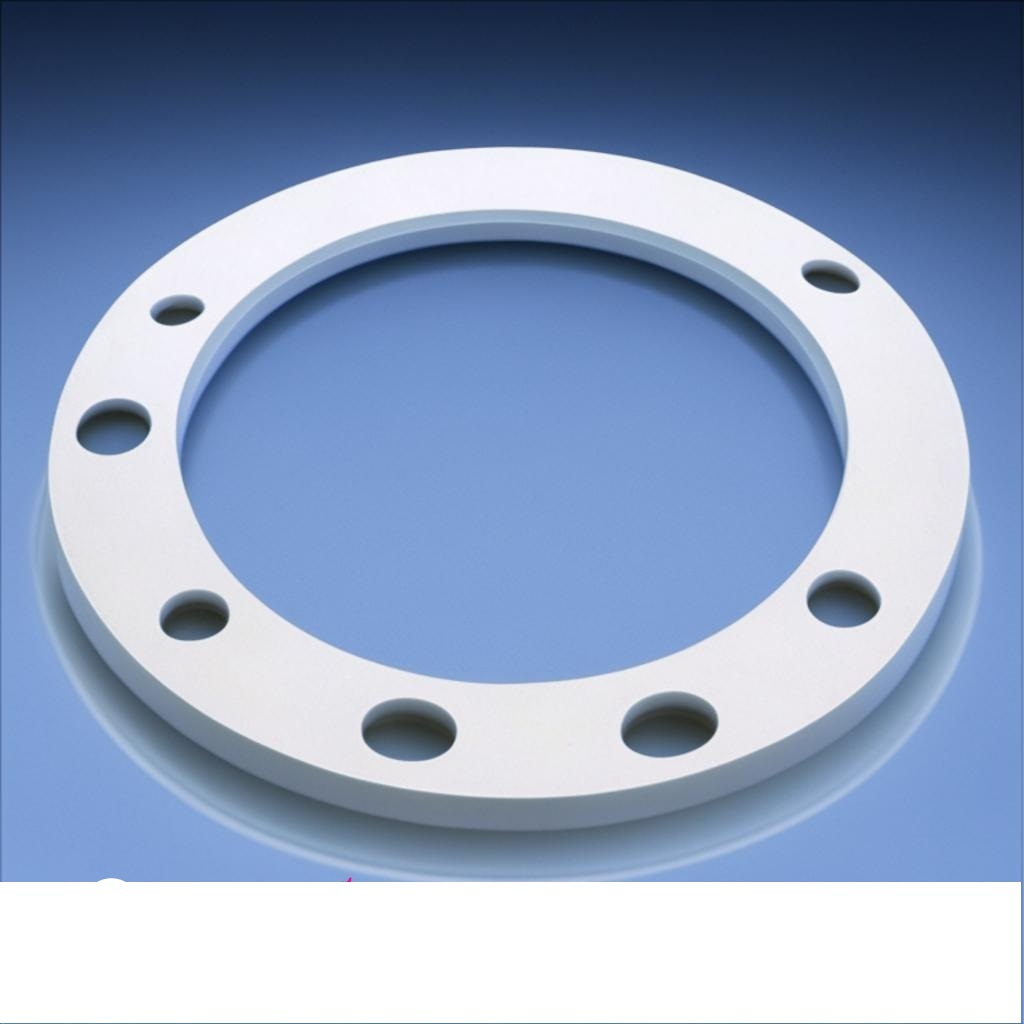

Modified PTFE

Modified PTFE

- Modified PTFE is a plastic with the lowest coefficient of friction and can resist very high temperatures of up to 260°C. It is the ideal sealant for even less flat flanges. Different materials are combined with PTFE powder, which serves as a filler and improves the quality of the gasket. For example: a silica filling, barium sulphate, or a full PTFE core with a soft microcell of expanded PTFE.

- Modified PTFE gaskets are resistant to almost any chemical and able to withstand strong acids and alkalis. As a result, these gaskets are put to highly versatile use in the (Petro-)chemical industry, the food industry, the pharmaceutical industry, and drinking water installations.

Prime Features:

Easy to use and replace Wide service scope, it can replace any asbestos gasket, seal-armoured gasket, metallic gaskets, etc. Diverse applications in pipelines, enamelled products, glass, rubber products, plastic, non-rusting graphite lining tower, heat exchangers Great interchangeability Easy to store and purchase

Specification:

Pressure: 19.6 MPa Temperature: -286°C to 320°C

Tanged Reinforced Graphite

Graphite

Tanged Reinforced Graphite

- Tanged graphite gaskets range of graphite sheet sealing materials is manufactured from highly pure exfoliated graphite flake, with/without a reinforcing metallic core. The standard product offers graphite with a carbon content of 98%, while for nuclear purposes, it's 99.85%.

- These gaskets are used in demanding industries such as petrochemical/refining industries due to the absence of any rubber or polymeric binders, making their stress retention levels high. This, in turn, ensures that the gasket stress applied upon assembly is retained during service.

- Various reinforce used are SS 304, SS316, SS321, SS341 and etc.

Prime Features

> Exceptional resistance to blow-out and crushing.

> Tough and versatile composite for high pressures.

> Strong composite construction with or without eyelets.

Specifications

> Density: 1.0g/cm3

> Compressibility (ASTM F36A): 15~35%

> Recovery (ASTM F36A): >/= 20%

> Pressure: 200bar

> Temperature: -240°C~+550°C

> PH: 0~14

Typical Applications

ASME B 16.21, DIN2690, And according to your requirements

Pure Graphite

Pure Graphite

- Pure graphite gaskets are widely used in all industrial sectors. They are found wherever enormously high temperatures can be found or substances that are distinguished by special aggressiveness. Pure graphite gaskets are thus especially deployed in the manufacture of pumps and/or exhaust systems.

- The mutability of these gaskets particularly makes them attractive for many areas. Pure graphite gaskets can, for example, be supplemented with stainless steel flaps or be impregnated with PTFE or copper to achieve better results and optimal application, including in drinking water installations.

- This includes the use of graphite foil, which makes it possible not to sacrifice the sealing quality even in the case of temperatures that exceed 450 °C.

EPDM (Ethylene Propylene Diene Monomer)

Rubber

EPDM (Ethylene Propylene Diene Monomer)

EPDM gaskets are made of a black plate finish sheet with superior resistance to weathering, ozone, and UV exposure. EPDM gaskets provide excellent chemical resistance* and good electrical properties. They also resist animal and vegetable oils, steam, water, and oxygenated solvents. This material meets ASTM D-2000-2BA specifications.

We cut gaskets from EPDM sheet gasket material to produce EPDM gaskets. Gaskets are cut from 1, 2, 3, 4, 5, 6, 8, 10 mm using EPDM material. Please note that EPDM rubber gaskets are not oil-resistant.

- EPDM gaskets are available in Raised Face and Full-Face specifications and can be manufactured as per customer requirements

- Operating Temperature Range: -200°C to -1000°C

Neoprene

Neoprene

Neoprene: A neoprene gasket is a type of gasket made from neoprene rubber, a synthetic rubber material known for its durability and resistance to oil, chemicals, and weathering. Neoprene gaskets are commonly used in a variety of industrial applications, including automotive, marine, and aerospace industries, as well as in plumbing and HVAC systems.

Neoprene gaskets typically have a working temperature range of -40°C to 121°C (-40°F to 250°F). However, this can vary based on the specific grade of neoprene rubber used in the gasket's construction and the environmental conditions it will be exposed to. Some grades of neoprene rubber can withstand temperatures up to 260°C (500°F), while others may have a lower temperature tolerance.

Wire Reinforced Neoprene

Wire Reinforced Neoprene

A Wire Reinforced Neoprene Gasket is made from graphite as a homogeneous material, reinforced by a metal mesh, foil, or tanged metal.

Material: A wire reinforced graphite neoprene gasket is typically made from a graphite sheet with a neoprene rubber binder and a metallic or non-metallic insert for reinforcement.

Thickness: The thickness of a wire reinforced graphite neoprene gasket can range from 1/32" to 1/4" or more, depending on the application and the required compressibility of the gasket.

Temperature range: A wire reinforced graphite neoprene gasket can typically withstand temperatures ranging from -40°C to 200°C (-40°F to 392°F), depending on the specific grade of neoprene rubber used in the gasket's construction.

Pressure rating: The pressure rating of a wire reinforced graphite neoprene gasket can vary depending on the specific application and the thickness of the gasket. They can typically withstand pressures ranging from 150 to 1500 PSI.

Chemical resistance: Wire reinforced graphite neoprene gaskets are highly resistant to a wide range of chemicals, making them suitable for use in corrosive environments.

Reinforcing insert: The metallic or non-metallic insert used in a wire reinforced graphite neoprene gasket can be made from a variety of materials, including stainless steel, carbon steel, or fiberglass.

Customization: Wire reinforced graphite neoprene gaskets can be custom-designed to fit a wide range of shapes and sizes, making them a versatile option for many different applications.